How are The Gummies Produced?

How are the gummies produced?

What are the raw materials used in the production of soft sweets?

The specific production process of soft candy?

Gummy is a very popular candy. It has a crystal clear appearance and has a strong chewy texture. It can be chewed for a long time. It is an ideal choice for many consumers to relax. There are many types of gummy candy. The most popular of which is the bear-shaped gummy candy, which has a huge market demand.

Many people want to know how the soft candies are produced. As a professional manufacturer of soft candies. We have very rich experience in the manufacture of soft candies. The following will introduce you to related matters related to the production of soft candies.

How are the gummies produced?

The processing and production of soft candies requires the use of high-quality raw materials, reliable formulas, and more professional equipment, and then gelatinize into a solution, boil sugar and glucose syrup, and add gelatin solution to the cooked syrup, flavor, coloring, citric acid, etc. It is produced by mixing with massecuite, storing, pouring, cooling, demoulding, conveying, adding varnish and packaging.

The raw materials used in the production of soft sweets:

1. White sugar

2. Glucose Syrup

3. Gelatin

4. Food flavors and colors

5. Palm oil

6. Corn starch

7. Citric acid

The specific production process of soft candy:

1. Melt gelatin first, and cook raw materials such as granulated sugar and glucose syrup in a sugar pot.

2. Add the melted gelatin to the cooked syrup, continue to heat, and stir evenly.

3. Add edible flavors and pigments to the cooked syrup for blending to produce different flavors and colors, and add citric acid to make it have a certain sour taste.

4. Pour the prepared syrup into the mold. There are a variety of molds to choose from, such as bear mold, worm mold, and heart-shaped mold.

5. In order to prevent the soft candy from sticking to the mold, a thin layer of cornstarch should be sprinkled.

6. It can be demoulded after cooling and solidifying for about 24 hours.

7. After demolding, the soft candies are transported into the rotating drum, and the varnish is added, and then the equipment is turned on at high speed, so that the soft candies can be evenly coated with the varnish and become more crystal clear, and at the same time, the excess starch can be removed.

8. Finally, use the packaging machine for packaging.

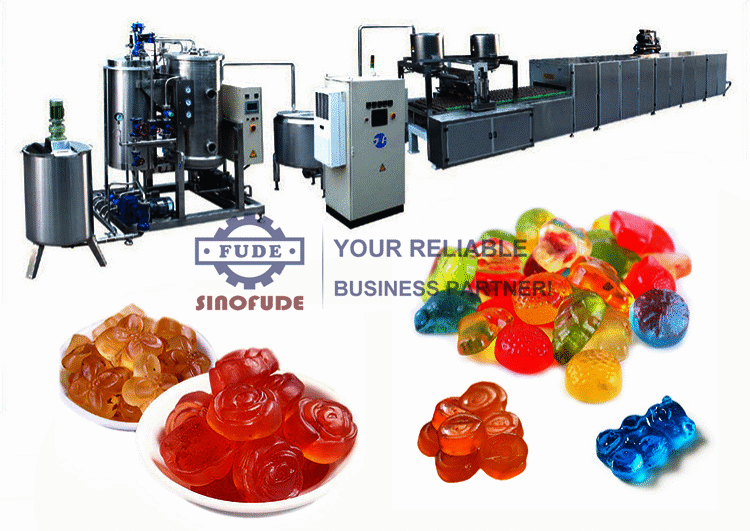

The above is a relatively standard soft candy production process. As a professional soft candy manufacturer, we are facing a very broad market and also facing huge competition. In order to improve our production technology level, we have purchased well-known in the industry Equipment-Gummy Machine for production, this equipment provides us with a strong driving force for development.

The soft candy equipment consists of sandwiched sugar pot, blending and storage pot, pouring machine, freezer, conveyor, sand roller (optional), polishing machine (optional) and other equipment, only need to replace the mold or the pouring head. The processing and production of single-color, double-color, multi-color and various shapes of soft candies or filled candies, etc., are very versatile. And the produced soft candies have a crystal clear appearance, a chewy texture and a very high quality.

Gummy Machine is currently a very advanced equipment in the world. It has a high degree of automation, a reasonable and compact structure, high production efficiency, long use time, stable operation, simple operation, low labor costs. It can be prepared according to actual production needs. The use method is very flexible.

With the help of this equipment, the soft candies we produced have been recognized by the market and further improved the brand awareness. We have reached a long-term friendly relationship with manufacturers. We hope that with our joint efforts, we can contribute to the soft candies industry. Make a greater contribution to the development of the company!

Telephone :+86-13917870833

Telephone :+86-13917870833 WhatsApp :8613917870833

WhatsApp :8613917870833 Email :info@sinofude.com

Email :info@sinofude.com